Views: 6 Author: Site Editor Publish Time: 2025-06-03 Origin: Site

How to choose the material drying system for the polyester staple fiber production line?

Here we have a table for your better understanding clearly.

Contrast table for vacuum dryer and continuous dryer system

( take 80ton/day capacity as example)

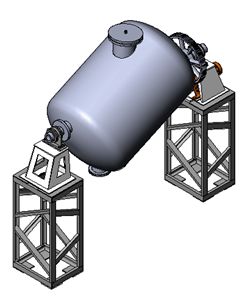

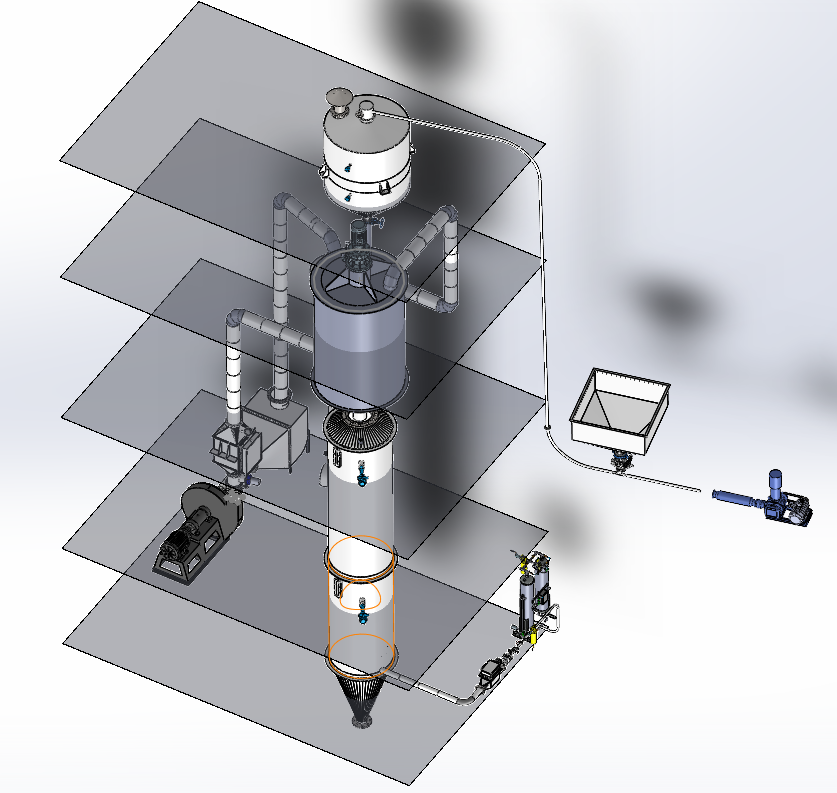

| Appearance |  |  |

| Quantity required | 16 sets of VC358 | 4 set of 1000kg/h system |

| Installation power | About 120KW+222KW ( vacuum pump) | 772KW |

| Heating method | Thermal oil, steam or electricity | hot air Circulation by electricity or thermal oil or natural gas direct burner. |

| Compressed air consumption | NONE | About 1200m3/h |

| Electric consumption | Around 18kwh per ton of fiber | Around 100kwh per ton of fiber |

| operator | 4 workers | One worker |

| Operation method | Manually | Automatic |

| Maintenance | Regularly,not easy, higher cost | Occasionally, easy, lower cost |

| Moisture content after drying | Around 100ppm | 30-50ppm |

| Quality control | Difference between each lot, not so even | Quality is even |

| Advantage | Suitable for colored fiber production to mix masterbatch | Suitable for large order quantity with same specification |

| Cost per ton of fiber | USD 23-38.5/ton | USD 15.4-23/ton |

| Fixed asset input | Around USD350,000 | Around USD 320,000 |

In conclusion, the machinery cost for vacuum dryer system is a bit higher, and it needs more manpower. But it is suitable for complex raw material such as masterbatch or powder for dope dyed fiber production, lump mix with pop corn material that has different weight. As for the continuous dryer, it has better control for the moisture, and save the cost. But its blowing system makes it cannot deal with too complex raw material. Thus, raw material type decided which system to adopt is more suitable for the polyester staple fiber production line.