| Availability: | |

|---|---|

|

| |

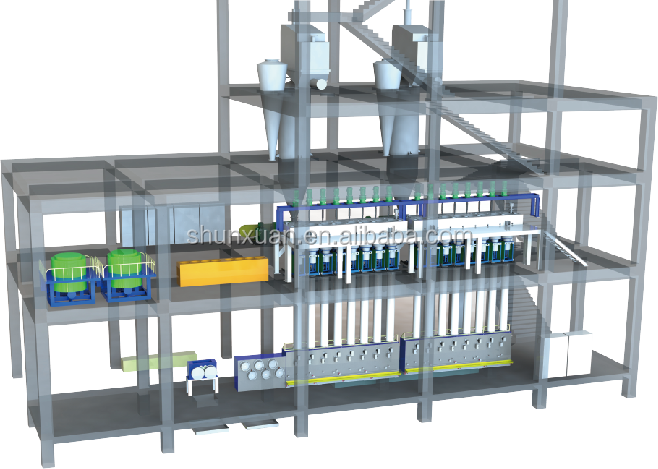

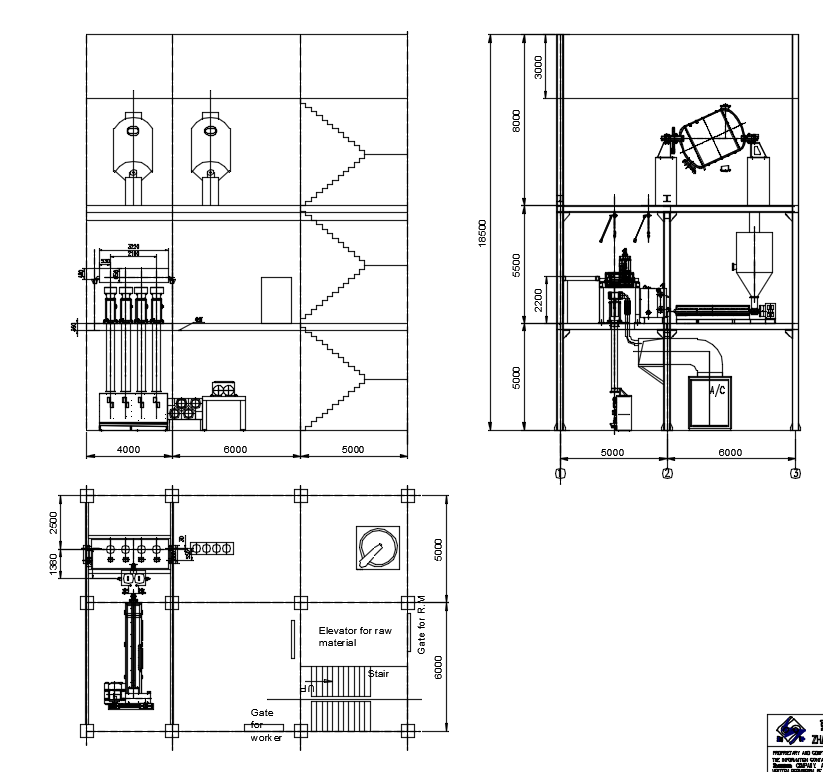

SHUNXUAN MACHINERY focus on the manufacturing of PRSF production line, we can you the PSF production line with professional technology and complete after sales service. Besides, we offer various spare parts related to PSF production line at customer's requirement.

Raw material: Bottle, pop corn material, lump, recycled packing belt, PET beer bottle.

Pop corn material comes from virgin filament, recycled filament, fabric, film or powder material.

Final product: 1.5D-30D solid fiber, 5D-15D hollow fiber. According to customer requirement, we also provide solution for PSF line to provide colored fiber, high tenacity fiber etc.

| Raw material | Bottle, pop corn material, lump, recycled packing belt, PET beer bottle etc. |

| Screw extruder Qty: | 1, 2, 3, 4, 5 |

| Spinneret Dia.: | dia.110mm-dia.328mm |

| Production capacity: | 10ton per day to 100 ton per day |

| Final product: | Solid fiber ( cotton fiber for spinning into yarn, colored fiber, wool type fiber, normal solid fiber for nonwoven fabric etc), three dimensional hollow conjugated fiber. |

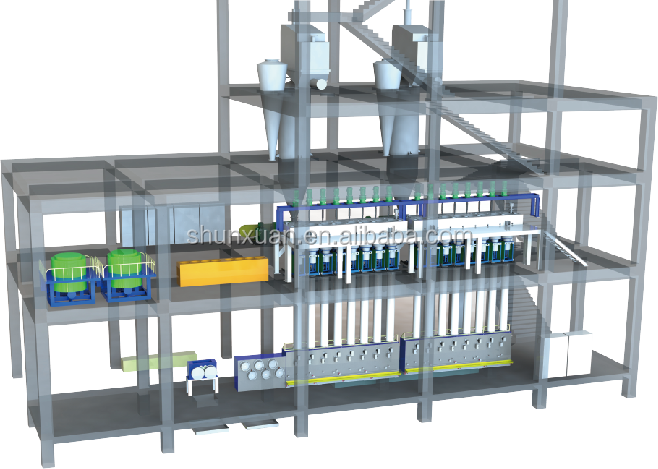

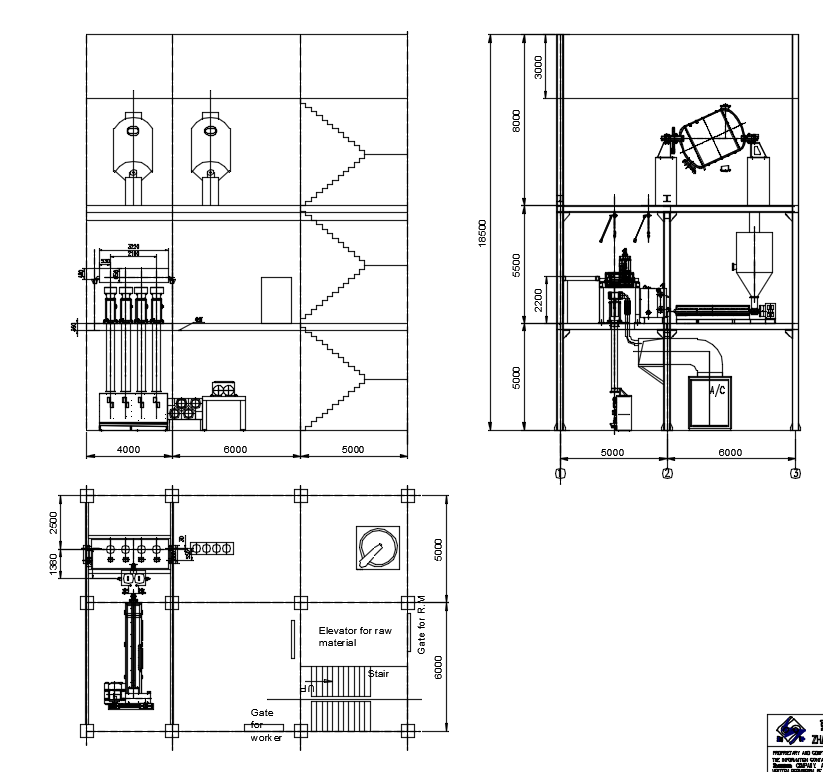

SHUNXUAN MACHINERY focus on the manufacturing of PRSF production line, we can you the PSF production line with professional technology and complete after sales service. Besides, we offer various spare parts related to PSF production line at customer's requirement.

Raw material: Bottle, pop corn material, lump, recycled packing belt, PET beer bottle.

Pop corn material comes from virgin filament, recycled filament, fabric, film or powder material.

Final product: 1.5D-30D solid fiber, 5D-15D hollow fiber. According to customer requirement, we also provide solution for PSF line to provide colored fiber, high tenacity fiber etc.

| Raw material | Bottle, pop corn material, lump, recycled packing belt, PET beer bottle etc. |

| Screw extruder Qty: | 1, 2, 3, 4, 5 |

| Spinneret Dia.: | dia.110mm-dia.328mm |

| Production capacity: | 10ton per day to 100 ton per day |

| Final product: | Solid fiber ( cotton fiber for spinning into yarn, colored fiber, wool type fiber, normal solid fiber for nonwoven fabric etc), three dimensional hollow conjugated fiber. |